Importance of Greening Automotive Supply Chain

The global auto components industry is estimated at US$1.2 trillion with a major share from India. As per the Auto Component Manufacturers Association (ACMA), the Indian auto component sector has been growing at 20% per annum since 2000 and is projected to maintain the high-growth phase of 15-20% till 2015. Increasing growth in the automobile sector will boost vehicle production, however, it also adds pollutants into the atmosphere during the entire lifecycle of vehicles. As per the report by US Environmental Protection Agency, Greenhouse Gases (GHG) emission from transportation accounted for 13% of global GHG emission in year 2004. Increasing concentration of greenhouse gases into the atmosphere causes climate change and it is a serious concern for industrial sector including auto-manufacturing sector.

This article outlines GHG emissions from automobile supply chain i.e. from auto ancillary sector. Greenhouse Gas (GHG) emissions from auto and auto ancillary sectors are major contributors to climate change. About 90% of GHG emissions in the life cycle of the vehicle happen at the stage of usage. Though the rest 10% GHG emissions are small on the overall scale, it’s a significant number in absolute terms. Of this 10% emission, majority of it takes place at the tier-I and tier-II suppliers’ end. Therefore, the sustainability initiatives cannot be complete without active involvement of auto parts suppliers.

With growing concern about the climate change auto manufacturers such as TATA motors, Ford, Volkswagen, Maruti-Suzuki, Hyundai and Toyota have already started quantifying their GHG emissions and mitigation activities. TATA Auto Components has set its mission to become carbon neutral. These companies are publishing their carbon footprints in annual sustainability and environment reports. All of these companies have auto assembly plants, while they rely on their suppliers for production of auto components. Therefore, major part of the GHG emissions occur at supplier’s end (Scope 3 GHG emission[1]) and need quantification to maintain GHG inventory. Subsequently these companies might ask the suppliers for quantifying their carbon emissions in near future.

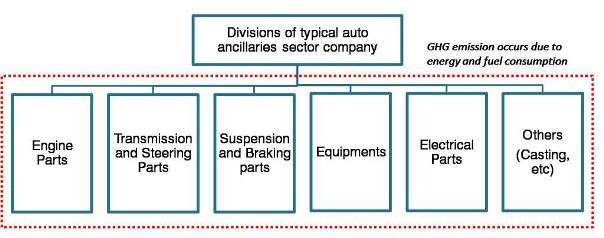

The following chart shows the GHG emission from typical units of auto ancillary industry;

Who are asking their suppliers to go green?

TATA Motors: TATA Motors is working with channel partners to reduce climate change impact in the supply chain. TATA motors have developed a unique initiative – Green Dealership for creating awareness and promoting good environmental practices and management systems in supply chain. The initiative aims at disseminating information on energy conservation and subsequently reduction in GHG emissions which could provide potential financial savings for channel partners.

TATA Motors have estimated the carbon footprint of their tier-1 supply chain and have initiated a CO2 abatement plan at the supplier level. The following are some of their key milestones – (1) Creating awareness amongst the vendors on climate change through a 20 minute info-module on the science, impacts, causes and abatement of climate change and related effects, (2) Sharing energy conservation ideas that are working effectively across our locations, (3) Collecting environment and energy related data through a questionnaire from Tier-1 vendors and estimating their footprint attributable to operations related to Tata Motors.

Maruti Suzuki: With the help of GHG management system in place and emission reduction plans, Maruti Suzuki has significantly brought down CO2 emission per vehicle in car manufacturing. At the Gurgaon Plant, CO2 per vehicle in 2010-11 came down by 15% compared to the previous year while in Manesar facility, CO2 emission reduced by 13% during the same year.

Maruti Suzuki sensitizes its suppliers about environmental issues and encourages them to take proactive measures to minimize their environmental impact. Periodic demonstrations and training programmes are organized for them on topics such as EMS, GHG management and environmental laws and regulations. In 2010-11, the Company encouraged its suppliers to supply material during the night shift. Currently, 26% of suppliers deliver material during the night shift. This has helped in reducing traffic congestion and pollution in and around Gurgaon city.

Maruti Suzuki encourages suppliers to shift their production facilities near its manufacturing facilities to reduce the GHG emisisons caused due to transportation. Both the Gurgaon and Manesar facilities have a dedicated Suppliers’ Park. Of the 19 joint venture companies, 11 are located in the Suppliers’ Park adjacent to the Maruti Suzuki Gurgaon and Manesar plants.

Volkswagen: Volkswagen Pune Plant in Chakan has undertaken various eco-friendly measures to ensure that the manufacturing processes adopted by the company have minimum impact on the environment. Since 2012, the company has also adopted ‘Think Blue Factory’, a global campaign of Volkswagen plants that aims to reduce the impact of production by 25% on the environment by 2018. In the first year, Volkswagen Pune Plant has achieved a reduction of 6.4% in specific CO2 emissions and 5.5% in specific energy consumption. Volkswagen is also influencing suppliers to embrace low carbon emission technologies in manufacturing of auto components.

Toyota: Toyota adopts proactive environmental measures throughout the vehicle life cycle. Toyota started influencing the company’s supply chain by continuing to train Tier 1 suppliers to conduct internal plant energy assessments for enhanced energy efficiency and in return reduced carbon emissions. Toyota in India has adopted “Green Purchase Guidelines” policy. Company ensures that its face “Toyota Automobile Dealers” adopt rigorous quality standards and sustainable work processes.

Some more auto companies might be added in the list in near future.

Automotive Component Manufacturers Association of India (ACMA) is also showing concerns about the negative impacts of increasing GHG emissions from Auto Ancillary industry. On 13th, 2013, the Automotive Component Manufacturers Association of India (ACMA) held the first national conference [2] in New Delhi on Minimizing Carbon Footprint for Sustainable Growth. Speaking on the theme of the conference, Mr. Vinnie Mehta, ACMA Executive Director, said:

“The adoption of green technologies in the automotive industry in India must be across the supply chain with active involvement of all stake-holders, including the Government. Worldwide, the automotive industry has used an array of technologies to reduce emissions; these have however varying applicability in the Indian context due to lower average speeds, road quality, congestion and the prevalence of small engines. We must encourage use of greener technologies that are local or can be easily localized at costs that are commensurate with the paying capacity of our people.”

Apart from stakeholder’s and other requirements, the immediate benefits of GHG management system for auto ancillary company is cost savings through energy efficiency. Managing GHG emissions let auto ancillary company to monitor the energy usage source wise. Largest GHG emission sources are also the most energy intensive. GHG management system let monitor the energy source and identify carbon footprint reduction projects internally, which can lead to cost savings for the organization.

[1] Scope 3 GHG emission or Indirect GHG emissions come from supply chain, third party/contractors’ energy consumption, employee travel, and use of consumables by the facilities.

[2] http://www.motorindiaonline.in/corporate/acma-meet-outlines-overall-strategy-to-minimise-carbon-footprint/

Other references:

Article by Agneya Blog http://agneyablog.wordpress.com/2011/01/27/bringing-sustainability-in-indian-auto-ancillary-sector/

Sustainability reports by various Automobile companies

Automotive industry is said to add many harmful pollutants into the atmosphere during the entire life-cycle of vehicles. So, It only makes sense to think of greening the same so that the atmosphere can be protected which should be primary focus of any business.